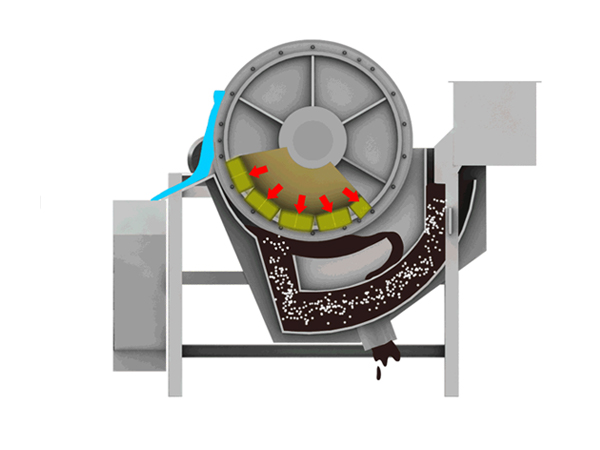

Magnetic separator uses different magnetic separation coefficient of various minerals to separate materials by means of magnetic force and mechanical force of the magnetic minerals. During the daily production, the wet magnetic separator is commonly used. Among wet magnetic separators, wet permanent drum magnetic separator is the best, which is the most commonly used magnetic separator.

Magnetic Separator

Feed Size ≤3mm

Capacity 1-280/h

Exported Countries Australia, Egypt, United States, Turkey, Laos, United Kingdom, Brazil, United Arab Emirates, Indonesia, Mexico, South Africa, Tanzania, Botswana, Uganda, Cote d'Ivoire, etc. Applied Materials

Applied Materials Magnetite, pyrrhotite, roasting ore, ilmenite, coal, non-metallic minerals, building materials, limonite, hematite, manganese siderite ore, ilmenite, wolframite, manganese ore, metallurgical manganese ore, manganese oxide, iron ore, kaolin, rare earth, etc.