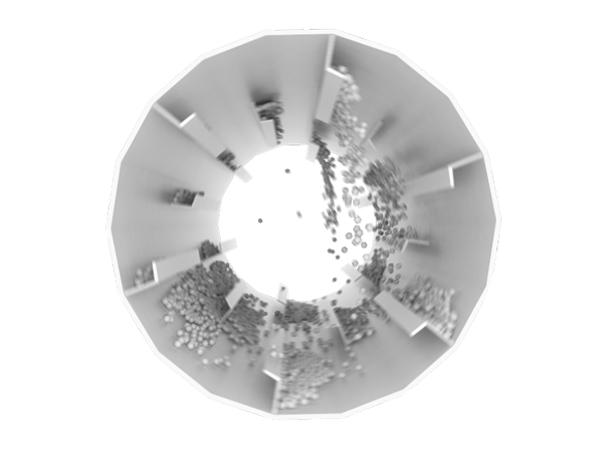

Rotary dryer is used for the drying process of materials, which is by far the most widely used drying equipment. When compared with the ordinary drying equipment, the heat and material of rotary dryer enters into the drying machine at the same end. The biggest characteristic of rotary dryer is that it has spiral lifter in the drying machine. In the drying process, lifting plate makes the material do rotary motion inside, and the material is dried in the process of hot air. In contrast, the drying effect of rotary dryer is more uniform. Rotary dryer also has other names, such as rotary drum dryer and rotary dryer plant.

Rotary dryer

Feed Size ≤25mm

Capacity 1.9-76/h

Exported Countries Estonia, Poland, Kosovo, Albania, Australia, Fiji, United States, Argentina, Pakistan, India, Egypt, Sri Lanka, Malaysia, etc.

Applied Materials Slag, gymsum, cement clinker, fly ash, cinder, kaolin, carbide slag, limestone, clay, river sand, quartz sand, etc. in metallurgy, construction materials, chemical engineering, coal washing, chemical fertilizer, mining, sand making line and other industrial fields.